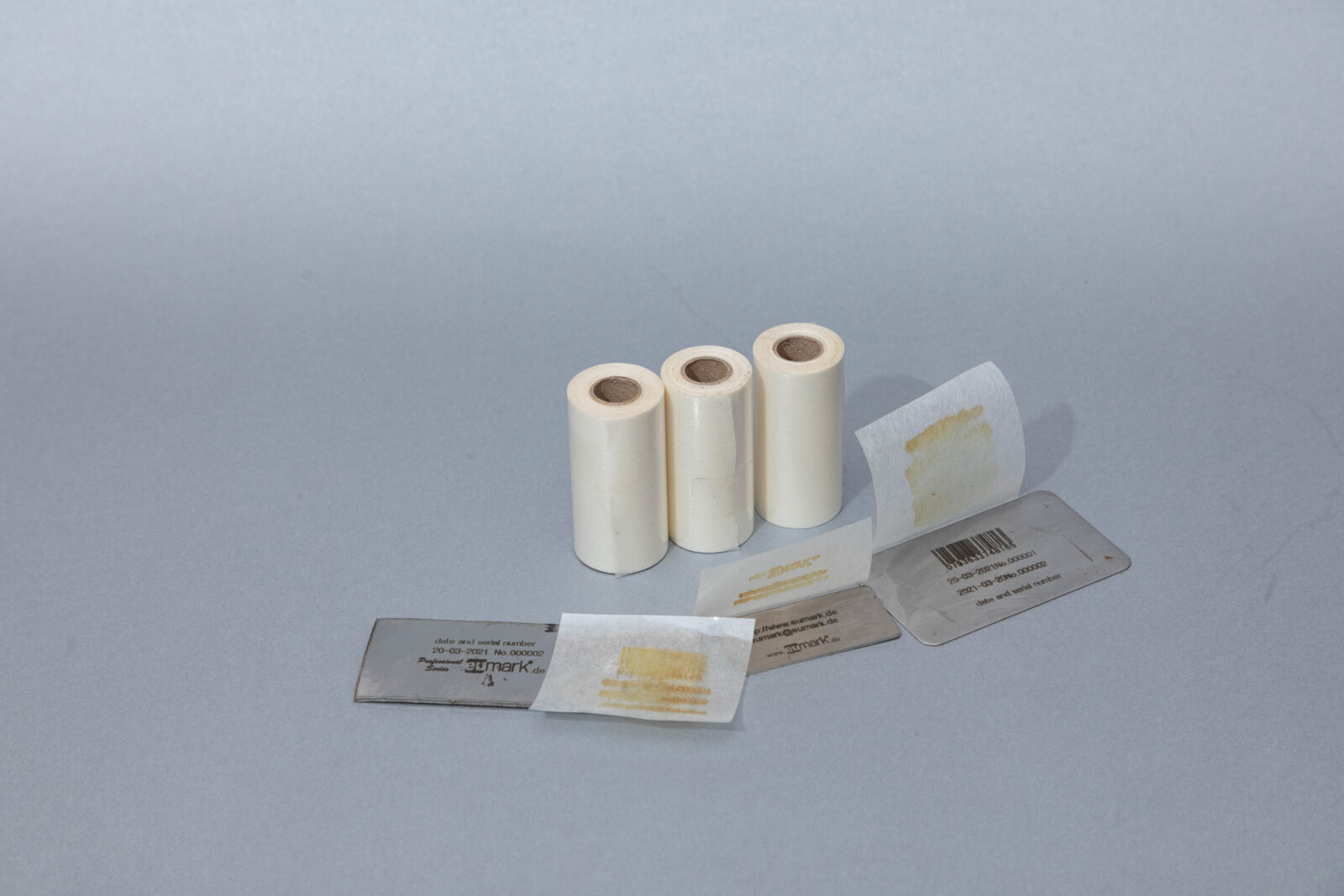

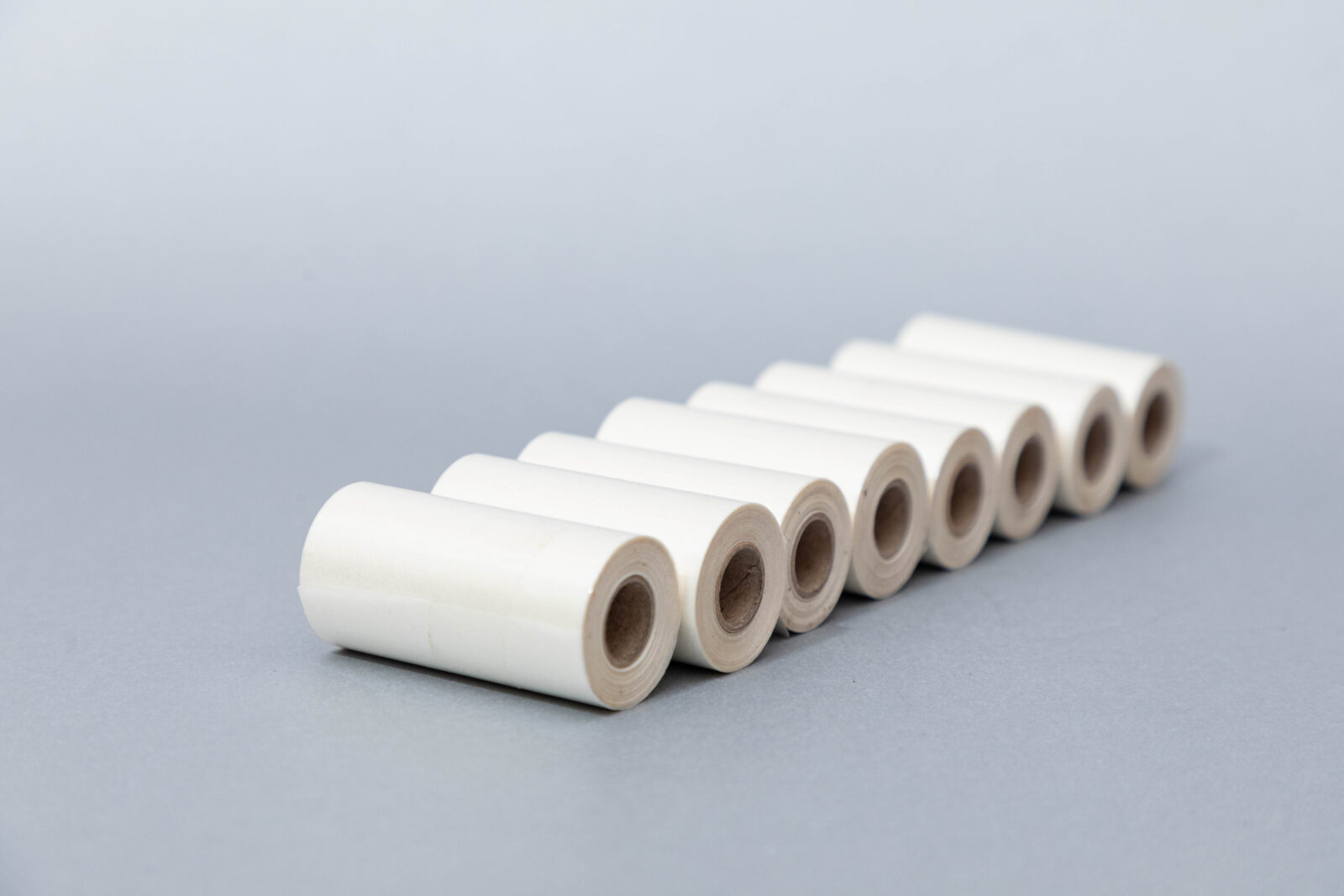

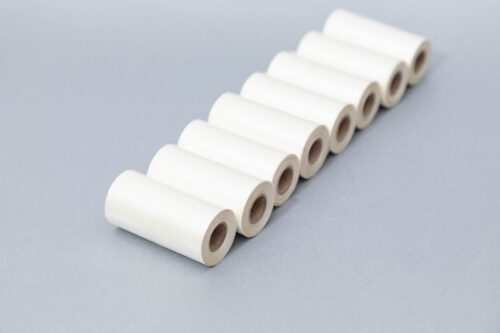

EUmark stencil printer 58mm with stencil tapes 6 pcs (58mmx10meters long)

199.99 €

FREE shipping world wide

EUmark stencil printer 58mm with stencil tapes 6 pcs (58mmx10meters long)

Finally we have solution to make quick, easy and very affordable stencils in home or workshop.

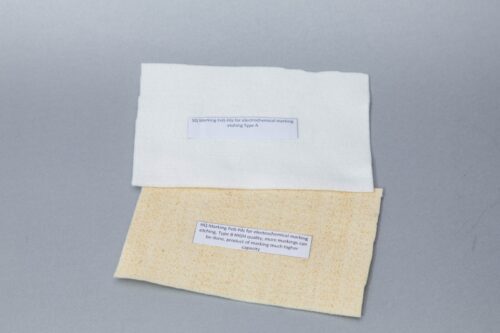

You need printer and stencil tape for marking (Electrochemical marking is electrochemical etching of metal surface)

When you use our stencil printer with stencil tapes you need only several min to make own stencil and quick mark.

Serial numbers, date, text, even logo can be done in just couple min!!!